AltoonaWorks.info Special Feature

Train Horns

Note: We have no horns for sale and all were acquired legally.

These horns are available for loan to local shortlines upon request.

Would love to own an H5 or even an H6 someday.

| HOME | ALTOONA-BUILT | REBUILDS | COMPLETED | HISTORY | TIMELINE | PHOTOS | OFFICE CAR SPECIAL | CURRENT OCCUPANTS | POWERPLANT | ROSTERS |

Notable Train Horn Resources | ||

|---|---|---|

| 5-Chime Consultants | LocomotiveHorns.info | Precision Parts NW |

| Featuring Train Horns in Our Collection | |||||

|---|---|---|---|---|---|

| Photo | Looking Inside | Brief Comments | Audio | Where on NS | |

|

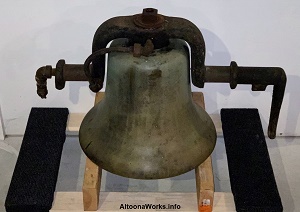

PRR GG1 Signal Line Whistle This six inch whistle was found in the cab of the PRR GG1 electric. It was used as the signal whistle where a crewperson could signal the engineer to stop or go etc. It's possible this small whistle was home-made in the PRR Juniata Shops. |

n/a | |||

|

|

Hancock 4700 Air Whistle Hancock was a major manufacturer of steam whistles. They marketed this air whistle but it was soon discovered that they just aren't loud enough when traveling at speed. Two of Conrail's E8s wore Hancock air whistles in the 70s and 80s. They fell out of use and you're unlikely to find one in use on anything other than a museum piece. |

Shop Air Video RTM M-25 Video |

n/a | |

|

|

Leslie A-125-247-PB This all-bronze A-125 dates to the 1950s. A-125s also came in aluminum. This particular horn comes from one of the Milwaukee Road's Hiawatha Locomotives. |

1930s - 1950s | n/a | |

|

|

Leslie A-200-LP This all-bronze A-200 likely dates to the 1940s. A-200-LP is the pre-1950 designation for the A-200-156. I got this horn, not so much because they were used on the PRR GG1 (this one likely was not), but more for its rich, low pitch sound. This horn weighs 50 lbs. You're not likely to see an A-200 in use today except on a museum piece. |

Shop Air Audio Shop Air Video RTM M-25 Video EBT M-7 Video Skip to 1:15. |

1930s - 1950s | n/a |

|

Leslie RS-31 Over the course of several months I pieced this single chime SuperTyphon together and painted it to represent the single note horns that were once on Conrail switchers. Those single note horns used the Leslie 25 and 31 bells. The 31 bell came from the Everett Railroad and the other two major parts came from parts available from collectors online. I was looking for a S power chamber, but they're harder to find; so I settled on an RS. |

n/a | |||

|

|

Leslie RS-3L For me growing up with Conrail, this horn screams "freight train." Union Pacific and BNSF were also users, but all Leslies have fallen out of favor and their numbers are quickly dwindling on Class Ones. This particular horn is from NS 3812 which was scrapped by Cresson Steel and sounds great after new gaskets were installed. The 'RS' power chambers give this horn a distictive squeal when starting to blow. |

Shop Air Audio Shop Air Video |

1970s - Present | Most unrebuilt former Conrail engines |

|

|

Leslie S-5T Known as the "King of Horns" because of its deep, commanding, and haunting tone, this horn is rare on class ones today and getting replaced with Nathans. Built in 1956, this particular horn has the original style tab-back power chambers that do not produce the squeal that the 'RS' chambers are known for. |

RTM M-25 Video |

1951 - 1970s | n/a |

|

Leslie RS-5T Known as the "King of Horns" because of its deep, commanding, and haunting tone, this horn is getting rare on class ones today and getting replaced with Nathans. The 'RS' power chambers give this horn a distictive squeal when starting to blow. |

Shop Air Video RTM M-25 Video |

1970s - Present | A few SD40Es, SD60Es, some former NW engines, and a few Dash9s | |

|

|

Nathan/AirChime MS1 The MS1 is the single note version of the M-series airhorns. You're not likely to find many of these around in regular service or even on museum equipment. The M series fell out of favor with the railroads because they're labor intensive. |

1952 - 1980s | n/a | |

|

Nathan/AirChime M3R1T This is rare variation of the M3. It was developed for use on Deleware & Hudson RS3s with the 2 and 4 bells facing forward and the tilted 1 bell facing backward at an angle to clear the cab roof. This horn was supposedly from a New York Central ALCO, but I suspect that's not correct. The M series fell out of favor with the railroads because they're labor intensive. They have to be voiced and in order to reverse bells, one basically has to disassemble the entire horn. |

Shop Air Audio | 1952 - 1980s | n/a | |

|

Nathan/AirChime M5 The M5 is probably the most sought-after horns among collectors for its melodic tone. The Southern was a big user of the M5 and the Rockhill Trolley Museum's Mack gas-electric also had one for a time. The M series was replaced by the easier-to-maintain K series and you're unlikely to find them in use on anything but museum equipment. This particular M5 dates to the 70s and was previously on an Amtrak unit according to the previous owner. The M series fell out of favor with the railroads because they're labor intensive. They have to be voiced and in order to reverse bells, one basically has to disassemble the entire horn. |

Shop Air Audio Shop Air Video RTM M-25 Video |

1951 - 1980s | n/a | |

|

|

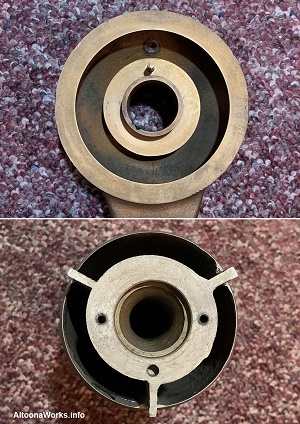

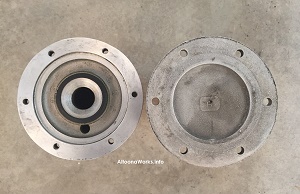

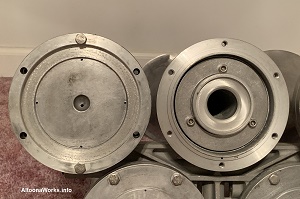

Nathan/AirChime P5 (old cast) Designed as a "low maintenance" alternative to the M5, the P5 sounds the same chord but with a brassier tone, especially the 'new cast' versions. As mentioned, there are two styles: old cast which blows the correct notes (Pat. Pending), and new cast (Pat. Pend.) (post 1976-77) which may or may not blow the correct notes. New-cast P horns typically squeal. On the right I have links to audio recordings of my old cast P5 and a new cast P5 owned by the Everett RR. |

Home Shop Audio New Cast Audio RTM M-25 Video |

19xx - Present | Most anything, especially former Southern units and road slugs |

|

|

Nathan/AirChime K3HA Union Pacific was a big user of the K3HAs on new power until it was replaced by the K3HL and K5 variants recently. This horn would sound the same as a K3LA, as the 'H' just means it uses the high profile manifold. |

Shop Air Audio | 1977 - Present | Some SD70ACUs |

|

Nathan/AirChime K5LA I purchased this horn brand new in 2007 and call it my "baby." While it may be a 'new' cast, my opinion is that it sounds great and has a very commanding tone. The set of debris covers is also brand new and was added in 2012. The 'raised letter' K horns began being made in 2007, first with the single-piece 1L bell, then the rest of them. Around 2014-15, new K backcaps came out that say Nathan Airchime instead of just Airchime. |

Shop Air Audio EBT M-7 Video Skip to 0:20. |

1975 - Present | The most common horn on NS and the USA, can be found on almost everything in various forms | |

|

Nathan/AirChime K5LLA The 'raised letter' K horns began being made in 2007, first with the single-piece 1L bell, then the rest of them. Around 2014-15, new K backcaps came out that say Nathan Airchime instead of just Airchime. NS 1021 (blt 3/2011) and NS 1141 (blt 11/2014) both confirmed to have 1L/1/2/3A/4A. NS 4001 confirmed to have 1L/1/2/3A/4A (arranged like a K5LA) post wreck repair. |

Shop Air Audio RTM M-25 Video EBT M-7 Video Skip to 4:03. |

2004 - Present | SD70ACes plus a few random units | |

|

|

Westinghouse DD-5 My first "train horn," this is the original horn off what was to become the Mt. Union Connecting Railroad's motive power. The DD-5 is a small horn that was common on industrial locomotives, track maintenance equipment, and even trucks. |

Shop Air Audio |

n/a | |

|

|

Westinghouse A-2 Another early addition to my horn collection is this Wabco A-2. These were usually used on industrial locomotives and sometimes first generation diesel switchers. |

Home Shop Audio | n/a | |

|

|

Westinghouse E-2 This horn is believed to be from a New York Central ALCO. The E-2 was popular on first generation power like the A-200, but not quite as popular. Also like the A-200, it fell out of use in favor of three and five chime horns. Finding an E-2 still in use today on anything other than a museum piece would be rare. |

Shop Air Audio RTM M-25 Video |

1940s-? | n/a |

|

|

Westinghouse E-2B-1 An early multi-chime Westinghouse horn, the E-2B-1 is actually three separate single note horns mounted on a special manifold. Never catching on, the E-2B-1 is fairly rare these days and you're extremely unlikely to find one in service other than a museum piece. Early versions of this horn, like this one shown here, used an E-2 with two B-6 horns while the remainder use the newer B-7s in place of the B-6s. Made of mostly cast iron with some aluminum, this E-2B-1 weighs 74 lbs. |

Shop Air Audio EBT M-7 Video Skip to 2:55. |

1940s-? | n/a |

| In addition to the above in my personal collection: I've cared for and reconditioned horns for the East Broad Top, Everett RR, and Rockhill Trolley Museum. | |||||